Principle of High Frequency Heating

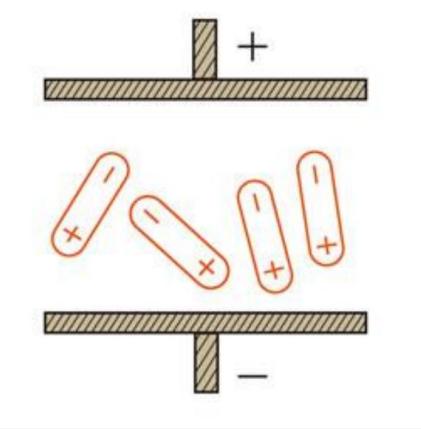

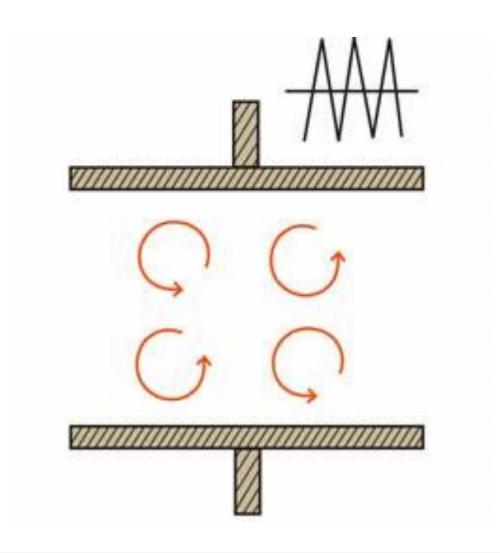

The medium is usually said insulator, such as wood, plastic, food, rubber, glass, glue agent and water, high frequency dielectric heating is the medium in the high frequency electric field, under the action of the electric field, medium molecules according to the electric field direction, due to high frequency electric field in order to speed the constantly changing direction, the dielectric material molecules in the original location of high-speed rotation or vibration, the intermolecular friction collision to generate heat, thereby achieving the purpose of heating ( see chart 1).

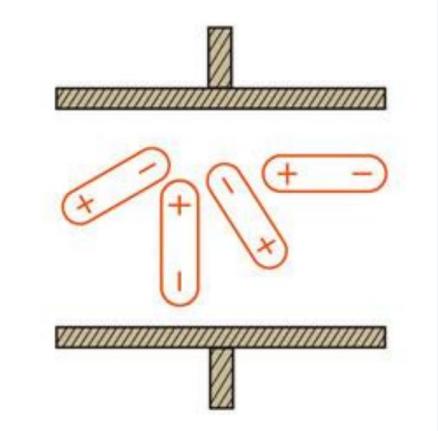

Disorder of arrangement of normal dielectirc molecules.

Orientation of dielectirc molecules in unidirection electric field.

High-speed rotation of dielectric molecules of HF electric field.

Main features

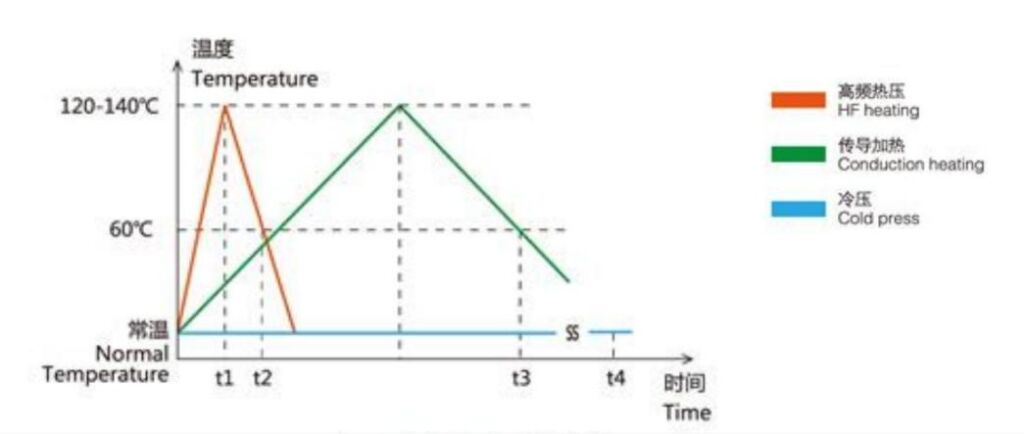

1. fast heating speed, high efficiency, if the workpiece thickness less than 20mm, conduction heating time is generally 1min/mm, is larger than the thickness, the time will be greatly extended,and the work piece thickness on the heating effect is much smaller, wood technology wooden using high-frequency heating in just two hours, and conduction heating needs five to six days ( see Figure two ).

t1—————High frequency dielectric heating

t2-t1————High frequency cooling time

t2—————Totally stitching time of high frequency

t3—————Totally stitching time of conductive heating

t4—————Cold press stitching time,generally over 4 hours

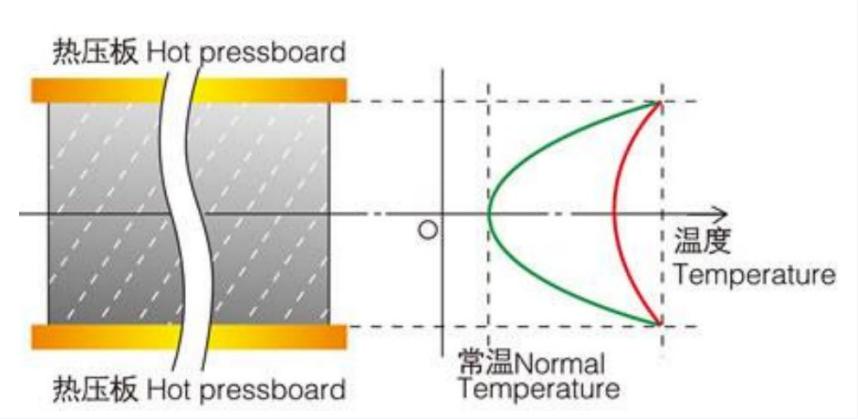

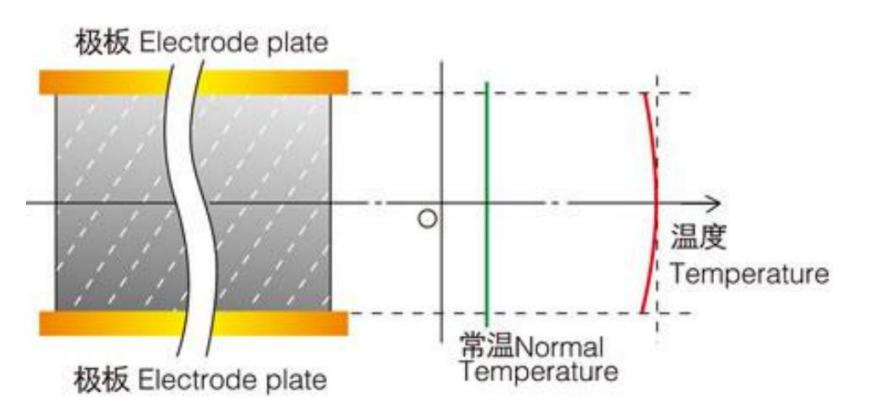

2. uniform heating: heat is generated from inside the object, the object in the electromagnetic field can make the uniform heating, such as wood technology wooden heating, the entire wooden home and reach the same temperature, which can effectively enhance the adhesive strength, enhance the quality of products ( see Figure three ).

Conductive heating: low temperature is in middile of workpart,high temperature is at two sides of workpart.

High frequency heating: High temperature is in the middle of workpart,low temperature is in the sides of workpart.

3. the heating process is easy to control : the electricity that is heat, power to stop heating, by adjusting the heating time control.

4. biological stimulation effect: sterilization, food processing, electrotherapy.

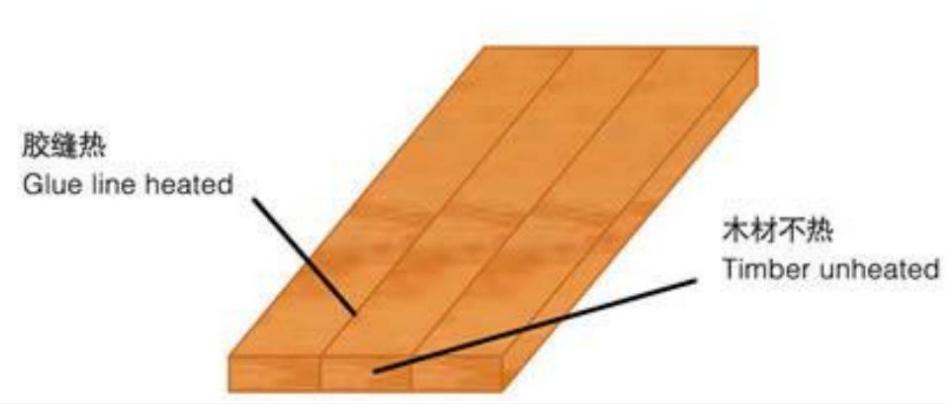

5. having a heating due to selective: in a certain frequency, a variety of material loss factor,absorption of electric field energy are also different. Proper selection of frequency, in order to together in a kind of electric heating material, can greatly improve the heating efficiency, reducing energy consumption, such as wood board, the electric field in the same in glue joints fever, and wood heat (see Figure four ).

6. being suitable for automatic production, small occupied space, low labor intensity.

7. environmental protection, no boiler, no dust, no smoke, no heat radiation, safety and health.